Finding the Invisible: How Systematic Air Leak Detection Transforms Efficiency and Sustainability

With electricity prices continuing to rise and environmental responsibility becoming increasingly important, organisations are actively searching for ways to reduce their energy use. When businesses review their power usage to find out where money is being wasted, often one of the biggest culprits (and easiest to address) is compressed air leaks.

So how can you make sure you’re not blowing power where it’s not needed? By implementing an effective and ongoing system for identifying, monitoring, and repairing air leaks.

The Leak Epidemic

Industry data suggests that the average plant loses between 20–30% of its compressed air to leaks. In poorly maintained systems, losses can climb as high as 80%.

Those leaks do more than waste energy. They:

- Cause system pressure fluctuations

- Reduce the effectiveness of air tools and processes

- Force compressors to cycle more frequently, shortening equipment life and increasing maintenance

Beyond the immediate cost impact, every unnecessary kilowatt consumed by your compressed air system has an environmental footprint.

Where to Look

Common trouble spots include:

- Couplings and hoses: Worn, damaged, or low quality fittings are a major source of pressure drop and leakage.

- FRLs (filters, regulators, lubricators): Incorrect installation, degraded seals, or neglected maintenance frequently lead to leaks.

- Drains: Manual condensate drains left cracked open can vent large volumes of compressed air around the clock.

- Threaded connections: Vibration and thermal cycling can loosen threaded joints over time, creating small but persistent leaks.

- Nose seals on air cylinders: Worn or damaged nose seals can allow significant compressed air leakage during cylinder operation.

Hearing the Invisible

Some leaks are obvious; you can hear the hiss as you walk past. However, in a typical plant environment, as many as 80% of leaks are effectively inaudible to the human ear, especially against background noise.

That is where systematic leak detection methods come in.

Traditional Methods vs New Technology

- Listening and soapy water

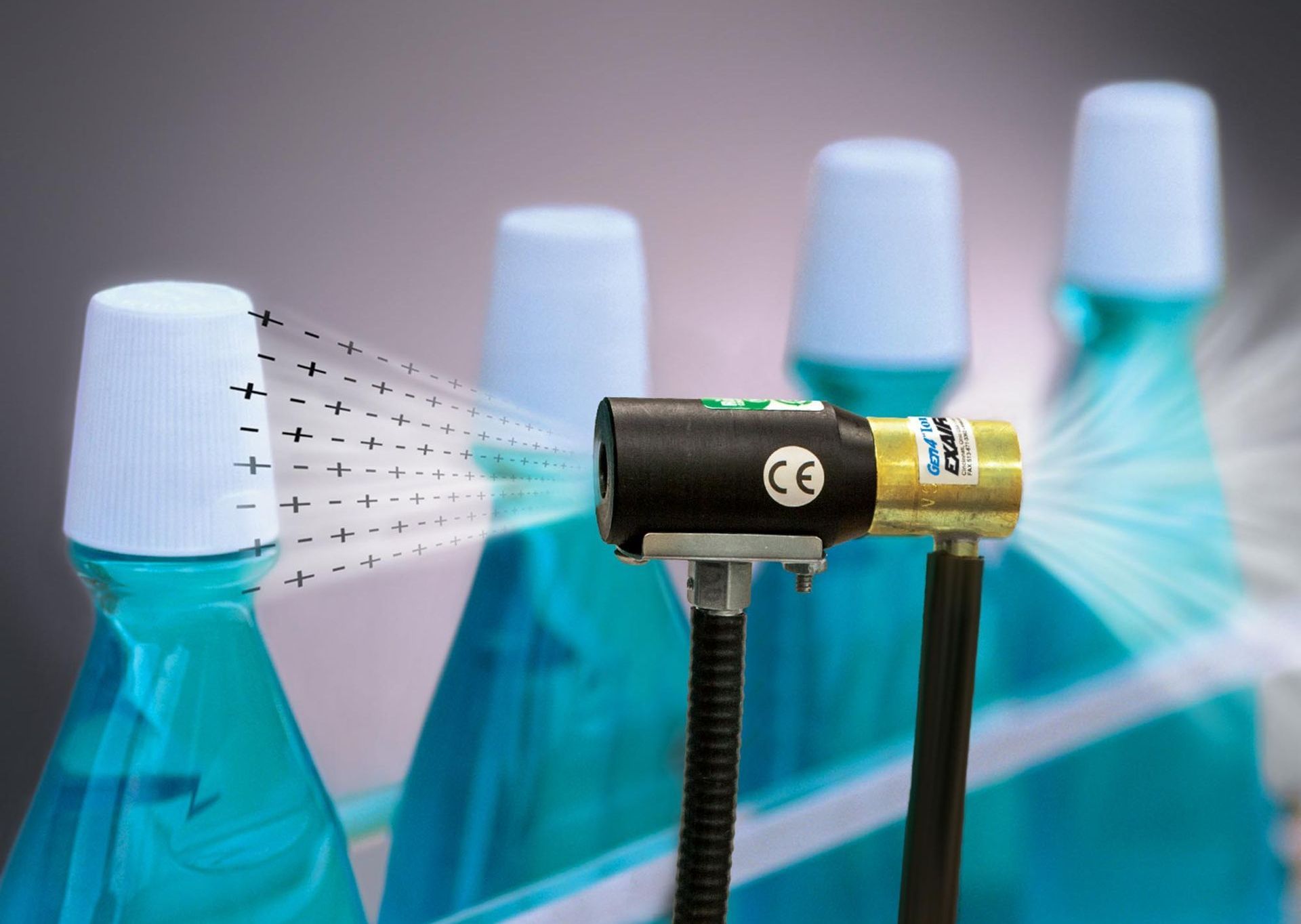

The simplest approach: listen for leaks and apply soapy water to suspect joints and fittings. Bubbles reveal the leak point. This method works, but it is labour intensive, messy, and difficult to scale across a large facility. - Ultrasonic leak detection (USLD)

Now considered industry standard, ultrasonic detectors “listen” for the high frequency sound generated by turbulent air escaping through a leak. They work reliably even in noisy plants and can pinpoint leaks as small as a pinhole. Modern day USLDs, such as the Prosaris system, also have cameras and monitoring technology, so you can quantify the costs of your leaks and monitor them over time.

PSL total air can carry out on-site compressed air leak detection surveys using ultrasonic technology, or supply ultrasonic leak detectors if you prefer to develop your own internal leak detection programme.

Repairing Leaks

Identifying leaks is just the first step, it’s a pointless exercise without repairing them. This is usually a straight-forward process; it could be as simple as tightening a fitting, patching a breakage, or replacing a seal. With an air leak survey from PSL Total Air, our expert technicians can repair most leaks on-the-spot, so you can start saving straight away.

The Bottom Line

The savings from a well-managed compressed air system are substantial. By treating compressed air as the high-value utility it really is, you can unlock meaningful cost savings, improve system reliability, and reduce your environmental footprint.

PSL total air can support you at every stage, from on-site leak detection and reporting through to supplying ultrasonic leak detectors, drains, and system upgrades that improve both your bottom line and your environmental performance.